Beamline Instrumentation Nanopositioning Applications

Positioning accuracy for beamline applications

Synchrotrons harness the power of electrons producing intense beams of X-rays, ultra-violet and infrared light. Super microscopes use this light to study anything from fossils to jet engines to viruses and vaccines.

Synchrotron engineers and beamline manufacturers need components capable of operating in an ultra-high vacuum (UHV) environment and may need radiation hard, non-magnetic components with the ability to perform at cryogenic temperature. After installation, system reliability is essential as the beamline is only accessible for short shutdown periods throughout the year.

High performance, high speed and extreme reliability

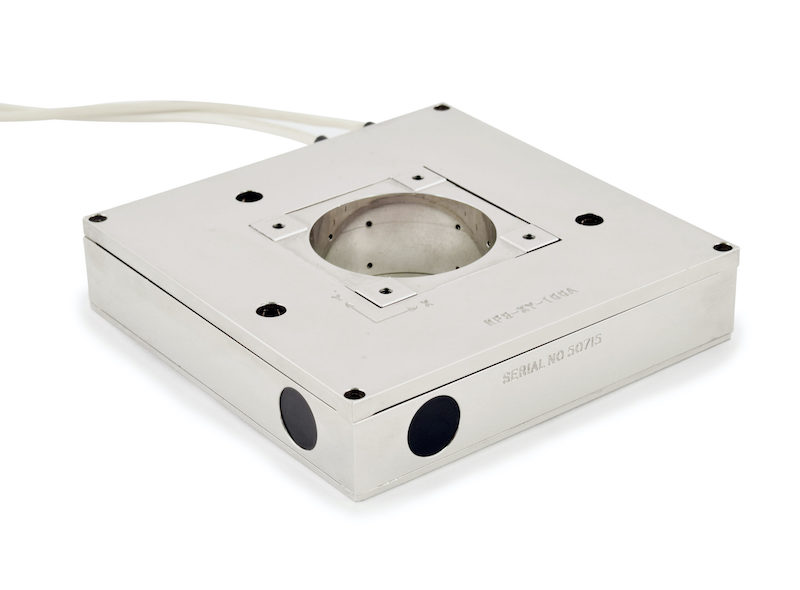

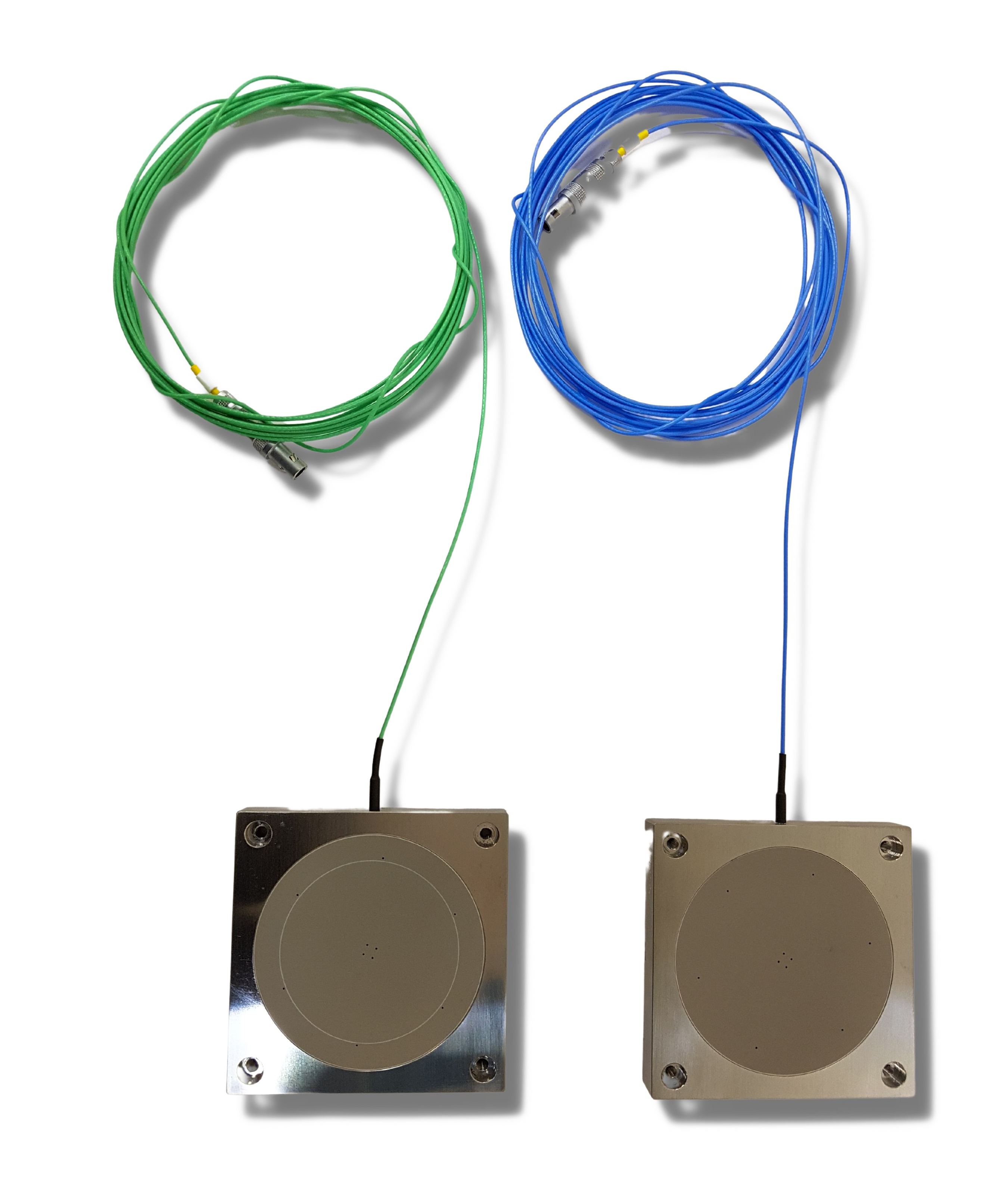

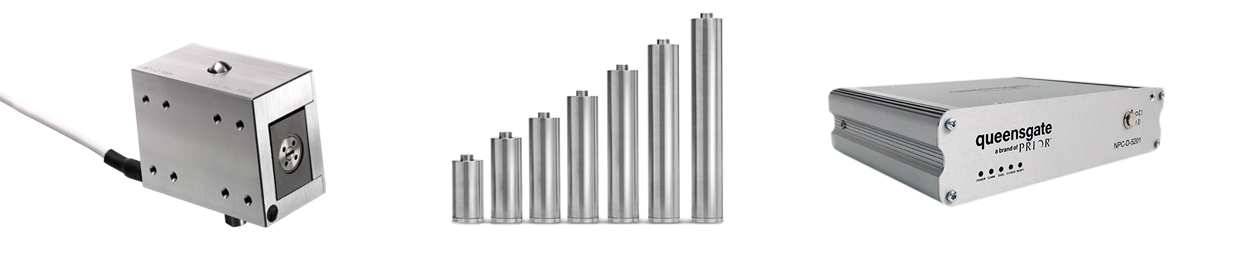

Queensgate offers an extensive product line of UHV compatible sensors, piezo actuators, and piezo stages. Whether standard or custom, our systems typically deliver decades of reliable performance, minimizing downtime.

Vacuum preparation

Parts that need to operate in UHV must have low outgassing. Queensgate sensors all use Kapton-insulated wires, and all bonding agents are selected using the NASA outgassing database. All systems are ultrasonically cleaned to remove oils and carbon residue from any metalwork, and system bake-out to remove any solvent residues before installation is recommended.

Download the Nanopositioning for Beamline Instrumentation Brochure.