Our new NanoCeramic (NC) NanoSensor series offers nanoscale metrology for highly demanding environments – such as ultra-high vacuum (UHV), high radiation or extreme temperatures (from 80 K up to 423 K).

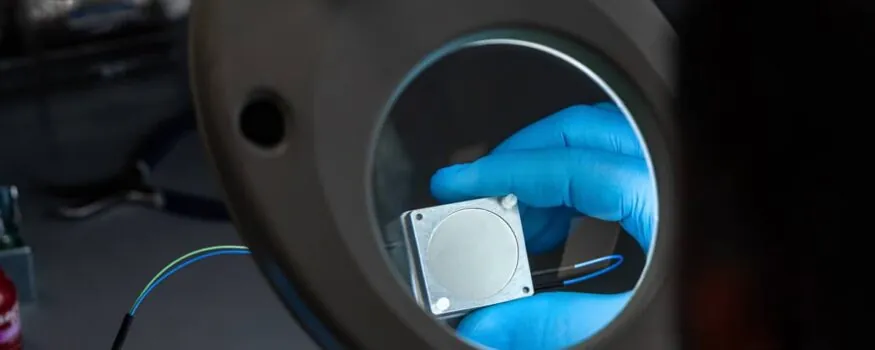

As with our NX NanoSensor series of precision positioning devices, the NC series is based on the principle of capacitance micrometry. Two gold-plated sensor plates – a target and a probe – form a parallel-plate capacitor, with the spacing of the plates measured using an electronic controller. A glass ceramic glaze is used to protect the sensor faces and prevent accidental shorting between the plates.

The NC series offers measurement ranges from 20 µm to 1250 µm, with frequency responses up to 20 kHz – making it ideal for vibration monitoring and detecting noise in precision instrumentation. They ensure linearity down to 0.05% and measurement resolution as low as 7 pm (RMS) in a non-self-heating assembly and with selected designs suitable for UHV operation down to 10-9 Torr.

The NC series are produced using military- and aerospace-qualified manufacturing techniques to ensure they meet the exacting performance specifications. The choice of housing materials for the various applications is also crucial for performance. Invar housings, for example, provide thermal stability at cryogenic temperatures (down to 80 K); stainless steel SS316 is ideal when matching the sensor’s expansion to a stainless-steel structure; and non-magnetic aluminum housings are best used when matching thermal expansion to aluminum structures.

Our high-quality digital controllers combine low-noise electronics with a 20-bit digital output and a 50 kHz update rate. The digital signal makes it easier for users to integrate the sensors into their existing control systems.

Application: Monitoring silicon crystal bending

Typical uses for the sensors range from long-term space missions to synchrotron light sources and a host of materials science applications.

One of the first NC NanoSensor deployments was monitoring silicon-crystal bending in a Bragg monochromator on a synchrotron beamline. This combined a measurement resolution of 2-5 nm with a 100 µm range, operating at cryogenic temperatures at around 80 K (-193 °C) in UHV conditions down to 10-9 Torr. The sensor housing and cabling was also able to withstand the maximum beamline radiation of 143 Gy/hr.

The NC series is an expanding product line. If the model required is not available, please contact us to discuss your requirements.

A longer version of this article first appeared on Physics World, December 2022.